Project Summary

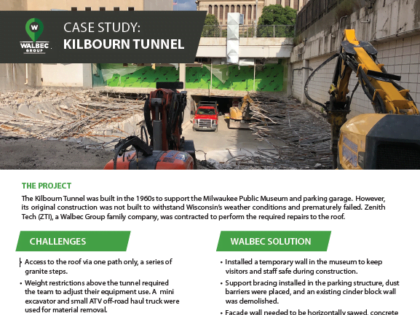

The Kilbourn Tunnel was built in the 1960s to support the Milwaukee Public Museum and parking garage. However, its original construction was not built to withstand Wisconsin’s weather conditions and prematurely failed. Zenith Tech (ZTI), a Walbec Group family company, was contracted to perform the required repairs to the roof.

Project Challenges

- Access to the roof via one path only, a series of granite steps.

- Weight restrictions above the tunnel required the team to adjust their equipment use. A mini excavator and small ATV off-road haul truck were used for material removal.

- Existing courtyard above the tunnel made forming the tunnel ceiling challenging.

- Pouring the deck to meet high and low points and two drains was a challenge.

- Pedestrian safety traveling to and from the courthouse and county jail was of utmost importance throughout this work.

Walbec Solution

- Installed a temporary wall in the museum to keep visitors and staff safe during construction.

- Support bracing installed in the parking structure, dust barriers were placed, and an existing cinder block wall was demolished.

- Façade wall needed to be horizontally sawed, concrete removed, forms installed, and concrete poured.

- Robotic demolition was used on the ceiling of the tunnel as an alternative to a traditional excavator to ensure worker safety. The existing roof design could not support its weight.

- Poured deck was same thickness throughout and followed multiple flow lines to ensure proper drainage.

- Using a traditional bridge paver was not possible and hand screeding was impractical. The ZTI team had to find an alternative solution.

- A Spider Screed from Ligchine™ International was used. This small laser screed was light enough for the form work to support and versatile enough to pour the intricate flow lines. The laser screed had a 3D total station control system that assisted crew in pouring to the exact specifications and city requirements.

- Upon achieving strength, the forms were stripped, waterproofing was applied, and the tunnel was reopened to traffic.

Case Study

Kilbourne Tunnel Milwaukee, WI