A new parking lot is more than a slab of pavement—it’s an investment in your customer experience, your property’s safety, and your brand’s professionalism. At Walbec, we believe that every project deserves structured planning and quality oversight, from the ground up—from aggregate to final striping.

Below, we walk through a practical guide to planning, budgeting, and executing a new lot for small businesses who want results that last.

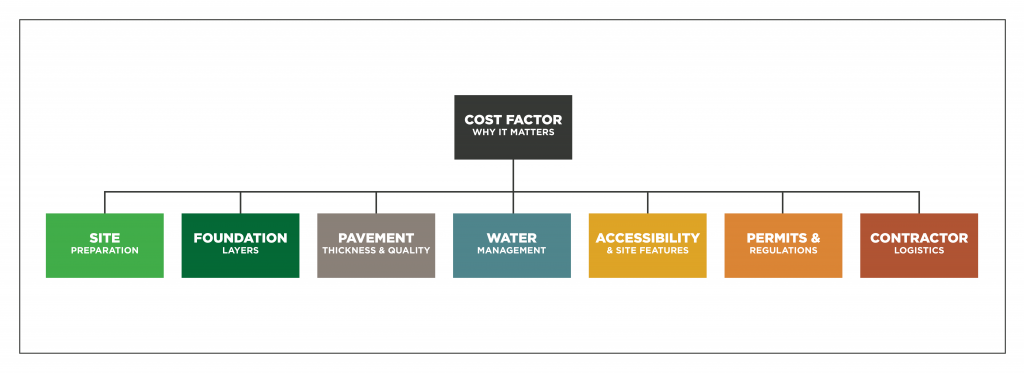

UNDERSTAND WHAT DRIVES COST

Parking lot projects vary widely—several factors influence your final cost. Here are the key ones:

Site Preparation — Clearing and leveling the area, removing old pavement, and preparing the ground can be costly, especially if there are soil or water drainage problems.

Foundation Layers — Building a solid base using crushed aggregate base course and compacted materials is essential for a parking lot that will last.

Pavement Thickness & Quality — Areas with heavier vehicle traffic need thicker pavement; using higher-quality materials extends the life of your lot.

Water Management — Installing gutters, drains, and retention systems to handle rainwater affects both the performance of the lot and its compliance with local regulations.

Accessibility & Site Features — Adding sidewalks, curbs, lighting, wheelchair-accessible ramps, painted lines, signs, and landscaping all contribute to the total cost.

Permits & Regulations — Obtaining approval from local authorities, meeting stormwater regulations, and complying with zoning and environmental requirements can increase your budget.

Contractor Logistics — The distance the contractor must travel, where they set up equipment, and the type of machinery they require all impact the final price.

We consistently emphasize to our clients that from production to milling and pulverizing to paving—sustainable, long-lasting asphalt solutions are what we do best. We are committed to a final product that will stand the test of time and look forward to building partnerships that do as well.

When budgeting, estimate a range (low to high) rather than a fixed number to include contingencies and optional add-ons. That gives you flexibility if unexpected site conditions arise.

MATERIAL CHOICE: ASPHALT VS. OTHER OPTIONS

As a contractor that provides concrete services as well, we firmly believe in the numerous applications where concrete is best. But for commercial parking lots, asphalt is the preferred choice for most small businesses in the Midwest.

Asphalt Advantages:

- Fast construction process that gets you back to daily operations quickly

- Simple, cost-effective maintenance and repair

- Better performance during Midwest freeze-thaw cycles

- Often lower initial cost, especially for larger lots

Walbec’s vertically integrated model—with aggregate sourcing and asphalt production—ensures consistency and quality control.

When Clients Might Choose Concrete

- Heavy static loads or hefty industrial traffic

- Aesthetic or architectural considerations—for this look, we offer specialty and decorative site concrete services

- Longer lifespan with less frequent major maintenance (but higher upfront cost)

In many cases, a hybrid approach—concrete curbs, walkways, dumpster pads or aprons with asphalt driving surfaces—offers a practical compromise.

PARTNERING WITH THE RIGHT CONTRACTOR

Your contractor is your guide through the entire process—your choice here impacts your cost, quality, and timeline. Here’s what to look for:

Vertical integration & material control. Walbec handles aggregate and asphalt production, allowing us to manage quality, logistics, and costs more effectively.

Design + engineering capability. You need a partner who can design drainage, site flow, grading, and compliance. Walbec provides complete engineering and civil solutions.

Reputation & project history. Review completed projects of similar scale. Walbec’s portfolio spans commercial, site development, and infrastructure work.

Transparency & communication. From initial estimates to project milestones, you’ll receive clear documentation and regular updates.

Safety, ethics & reliability. Walbec’s commitment to safety and ethics guides our approach to every build.

DESIGN FOR LIFESPAN & MAINTENANCE

- Plan for maintenance from day one—it’s one of the smartest decisions you can make.

- Design traffic flow to minimize sharp turns and reduce stress on pavement edges.

- Match pavement thickness and structural design to your anticipated vehicle loads.

- Install efficient drainage to prevent water damage and freeze-thaw cracking.

- Schedule regular treatments: sealcoating, crack sealing, patching, and restriping.

- Monitor your lot’s condition and fix small problems before they grow.

A well-maintained lot from a quality contractor delivers decades of performance at a lower total cost.

If you’re ready to move from planning to execution, Walbec is here to partner with you every step of the way. Our expertise in asphalt, aggregate, engineering, concrete, and construction means you benefit from consistent quality, local knowledge, and a team committed to exceeding expectations.

Contact us to discuss your vision for your business exterior. We’ll assess your site, provide a clear budget, and deliver results that drive value for years to come.